Robot programming

Our services support machine and line construction companies in programming industrial robots. Thanks to our experience in the automotive industry, we can effectively respond to the needs of industrial process robotization.

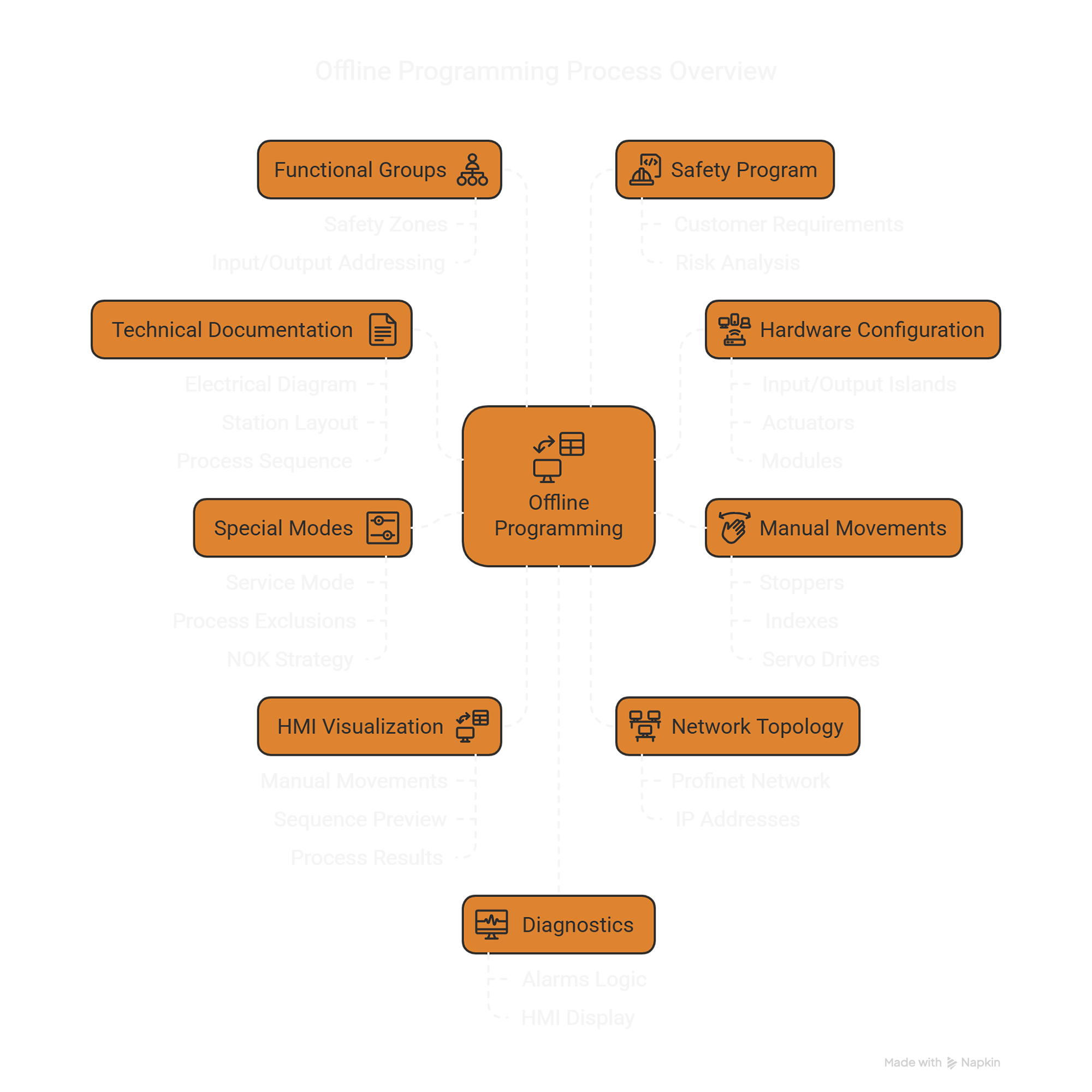

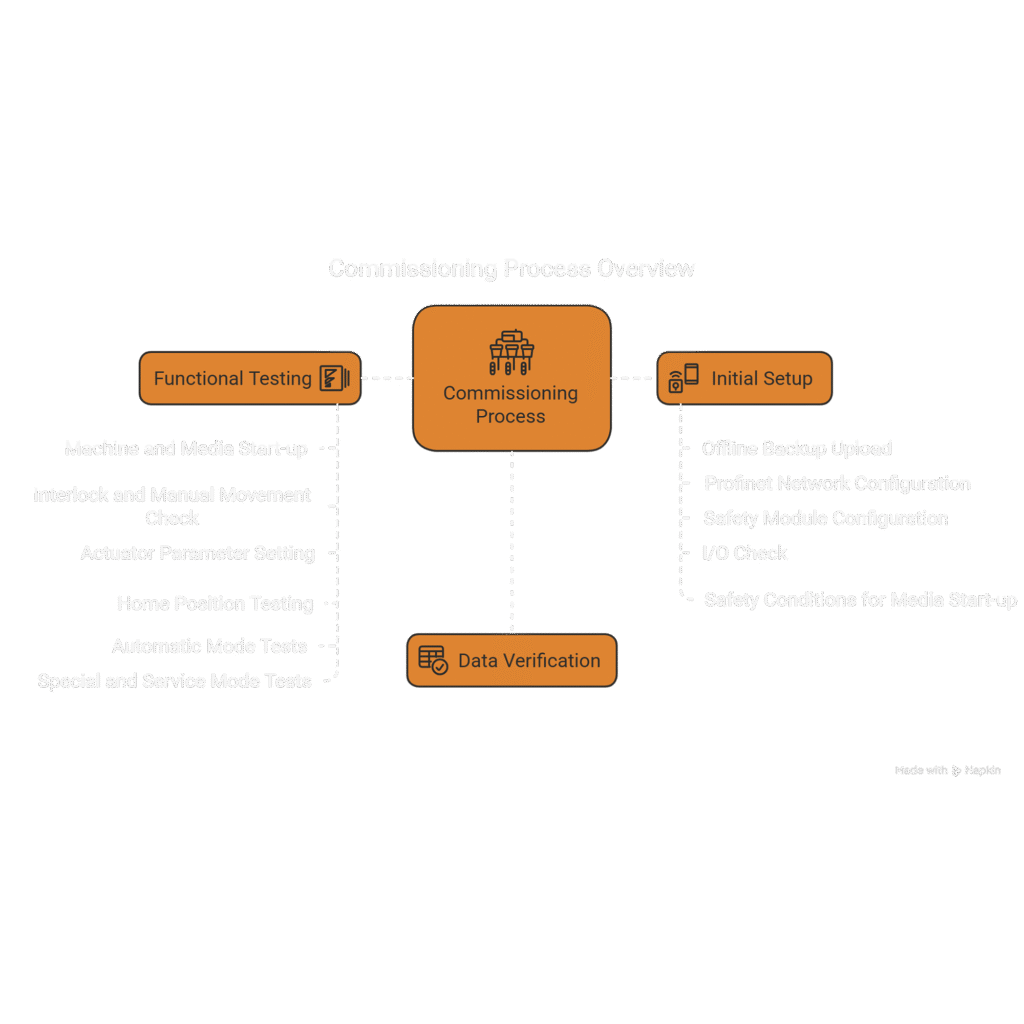

Amister’s team of 6 roboticists performs comprehensive services from the preparation of off-line programs, through the commissioning of robots at the customer and end user, to the creation of technical documentation and production support.

Robot programming

Our services support machine and line construction companies in programming industrial robots. Thanks to our experience in the automotive industry, we can effectively respond to the needs of industrial process robotization.

Amister’s team of 6 roboticists performs comprehensive services from the preparation of off-line programs, through the commissioning of robots at the customer and end user, to the creation of technical documentation and production support.

What does robot programming include?

Key advantages of working with Amister

We have observed that our clients consistently value not only technical competence, but also the reliability and professionalism of their automation partners. At Amister, we strive to meet these expectations by delivering comprehensive and tailored solutions at every stage of the project.

Our approach is built on key principles that make a tangible difference in each collaboration:

Low turnover of employees on a project

It is an industry standard to have high turnover during projects, leading to delays and organizational problems. We take workload into account at the planning stage to ensure team stability throughout the project. The client can rely on an unchanging team, which speeds up implementation and minimizes the risk of errors.

Replacement procedure

Often projects are paralyzed by staff shortages on the integrator’s side. This happens due to random cases or too many projects running simultaneously. That’s why at Amister we have implemented the principle of employee substitutability. It assumes that each employee has a substitute with an analogous level of competence and knowledge of the project. Thanks to this, random accidents or natural rotation of the team in the project do not paralyze the implementation of projects.

We identify with clients’ projects and needs

Many projects are implemented mechanically, without understanding the specifics of the industry and the client’s goals. At Amister, we are characterized by a proactive approach and understanding of our clients’ needs. As a result, the client receives solutions that are perfectly tailored to their requirements.

Team leader to coordinate Amister work and communication with the client

Clients often have to communicate with many people, which makes project management difficult. At Amister, each project is coordinated by a dedicated team leader, who is responsible for organizing the work and staying in touch with the client. The client communicates with one designated person, which streamlines project management and ensures transparency of activities.

Last projects

Dana Amal Sweden

rotor assembly line

Lear Tychy

seats gluing station

Star Assembly SRL

eATS line on basis of Daimler Powertrain Standard

Stellantis Mirafiori

assembly line for transmission

Customers and locations where we did projects

Star Assembly SRL

Sebeș, Romania

Audi

Gyor, Hungary

BMW

Steyr, Austria

Stellantis

Mirafiori, Italy

BMW

Dingolfing, Germany

Daimler

Brühl, Germany

NIDEC

Niepołomice, Poland

Skoda

Mlada Boleslav, Czech Republic

Liebherr

Bischofshofen, Austria

Festo

Budapest, Hungary

Daimler

Untertürkheim, Germany

Dana

Amal, Sweden

Scania

Södertälje, Sweden

Volkswagen

Polkowice, Poland

Volkswagen

Salzgitter, Germany

Daimler

Redford, USA

Daimler

Kassel, Germany

Getrag

Köln, Germany

Getrag

Bordeaux, France

Daimler

Jawor, Poland

Bosch

Charleston, USA

Magna

Tychy, Poland

ZF

Toluca, Mexico

Robot programming – certification

Daimler Integra 6

KUKA SafeOperation

Fanuc DCS

ABB SafeMovePro

Need Robot programming?

Upgrade your systems with our expertise!

FAQ – Frequently asked questions

How long does a typical project preparation stage take?

A typical project preparation stage can take from a few weeks to several months.

It depends on the scale of the project, i.e. the number and complexity of machines and their components, as well as the functions and processes they support.

What determines the cost of robot programming in a given project?

The cost of robot programming in a given project depends on:

– the complexity of the system, including the number of controlled devices and the complexity of the control logic

– the brand of the robot and the cost of the software and licenses needed for programming.

– the length of the tests performed

– the amount of project documentation that needs to be prepared

What information is needed for an accurate project quote?

For an accurate and efficient project quote, we need a detailed description of the technical requirements, i.e.:

– technical drawings (including layout if production lines are involved)

– description of how the machine and/or the process itself works

– list of suggested components

– work schedule, if available

– control concept, if available

What robot brands do you work with?

We work with KUKA, FANUC, ABB, Kawasaki, Yaskawa, and ESTUN robots

What programming environments are used for simulation?

We mainly work with environments dedicated to the specified robot brand, e.g. Kuka SimPro, Kuka WorkVisual, Fanuc RoboGuide, ABB RobotStudio, K-Roset.

What safety systems do you use? Are the programmers certified?

Safety systems depend on the robot supplier. We mainly use Kuka SafePro, Fanuc DCS, and ABB SafeMove. Our programmers are trained and certified in the above-mentioned systems.

What processes do you have experience with?

The industrial robot programming team has experience with processes such as:

– Welding

– Gluing

– Twisting

– Riveting

– Welding

– Transfer

– Palletizing

– Vision systems

Do you design systems from scratch or modernize existing installations?

We offer commissioning of new systems from scratch, as well as modernization and improvement of existing installations.

Do you offer training for production and maintenance personnel on the installations you commission?

Yes, in almost every project we carry out, we conduct training for operators and maintenance personnel in the final commissioning phase.

The scope, time, and place, and even the language of the training are determined with the customer.

What sets you apart from the competition, why choose Amister?

We approach each client individually and treat our relationships as partnerships. We offer a professional approach based on openness to client requirements and expectations, consulting, problem solving, and full commitment to the tasks entrusted to us. This is evidenced by a large number of satisfied customers and references we have received during our many years of operation.

How is the work of the development team organized during a project?

A project team is selected from among the employees and supervised by a Project Manager responsible for dividing responsibilities within the team and communicating with the customer. The Project Manager coordinates the team’s work and ensures that the project objectives are met. Regular project meetings allow us to monitor progress and quickly resolve any issues that arise.

Who is responsible for coordinating activities during the system launch phase?

The Project Manager is responsible for coordinating activities during the system launch phase, supervising the schedule and communication between teams. He is supported by a technical leader who takes care of technical issues and smooth implementation. This ensures that the launch process runs smoothly and according to plan.

Do you provide onsite support during testing and production launch?

Yes, the specific nature of our work requires it.

How does communication with the client proceed during the project?

Communication with the client during a project at Amister is based on transparency and regular dialogue. At the beginning of the project, expectations, schedule, and preferred communication channels (e.g., email, online meetings) are established. During implementation, the customer receives regular progress reports, and key milestones are discussed and approved to ensure compliance with requirements. Amister emphasizes quick response to questions and flexible adaptation to changes requested by the customer. Final project implementation includes a detailed review of results and after-sales support, building long-term relationships.

What kind of service support do you offer after the project is completed?

After the project is completed, Amister offers comprehensive service support, including system monitoring and quick response to user requests. We provide updates and fixes to keep the system running smoothly and securely. Additionally, we offer the possibility of developing and implementing new functionalities according to customer needs.

Contact us – we’ll respond within 24 hours!

Do you have questions about production automation? Fill out the contact form, and our team will get back to you within 24 hours – either by phone or email.

During the conversation or correspondence, we will define the scope of work and services you are interested in. Then, we will conduct an internal analysis of your inquiry to prepare the best possible solution.

Within a maximum of 5 business days, we will get back to you with information on the next steps.

Take the step towards modern automation – fill out the form now!